Bdsm is how I learned what I was doing was unsafe and dangerous. Like logically I knew what consent was, but I didn't realize talking about things first, having after care, and doing that preparation and after work were important for the safety and well being as the sub (me in those situations). I wanted complete uncertainty and fear, which came most easy by not doing those things and fucking the first random guy who wouldn't question those demands. Kinda weird how, now, 5 years later, I'm all fucked up about it and crave it like it's a drug. Gonna be honest, wetfish has been a safe outlet to talk about it, bc the topic is so taboo. NC is so hot, it feel addicted and crazy without it

...

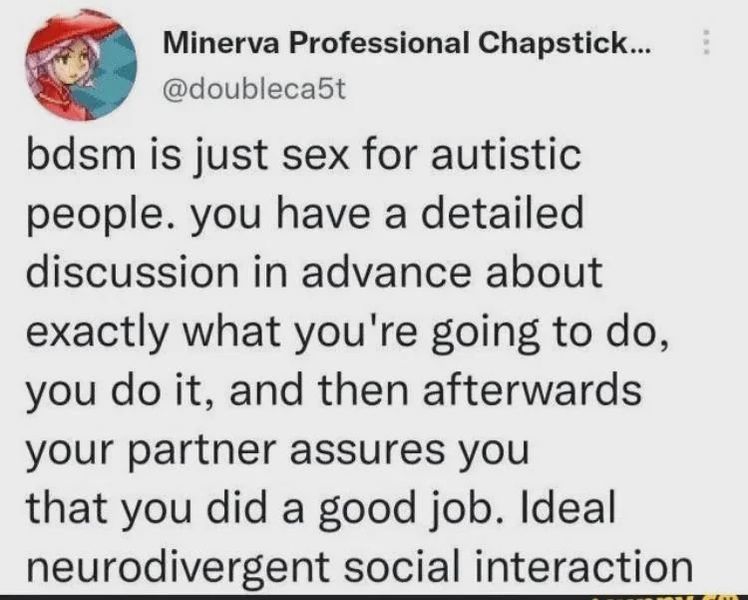

Ugh maybe I'll figure out how to make cnc actually interesting and work.maybe I'll be able to find an autistic badie who can help ... one day. Lmfao.

🥲 🔫